0086-371-86560898

Jaw crusher is generally used as the first to break the ore. jaw broken stone machine crushing fineness is adjustable, so users can be adjusted according to the rock breaking machine equipment granularity consultation requirements, the specific adjustment method, explained below about:

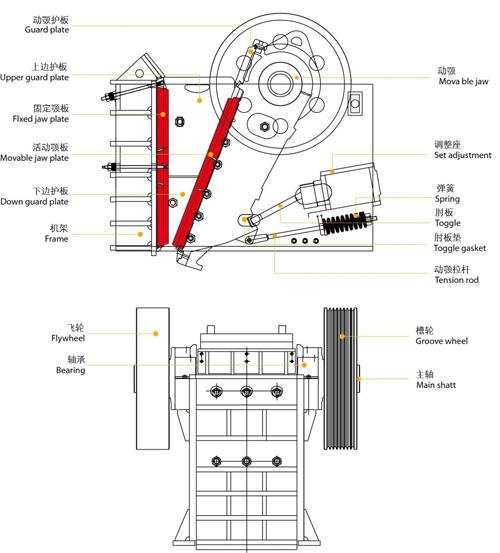

1, plate action principle regulating device is placed behind the rear toggle plate bearing a regulator plate, number plate or when changing the thickness of the toggle plate or migration or backward, can reach the discharge opening width adjustment purposes. This adjustment is simple structure, compact, weight increase much, therefore, very suitable for large and medium-sized jaw broken stone machine, is the stress of a high degree of distinction between regulating device.

2, the electronic control adjusting mechanism can very quickly and efficiently achieve adjustment and testing work Jaw rock breaking machine, you can use during the collection when the microcirculation changes stroke adjustment mechanism makes automatic recovery stress induction. In this way the role of regulator, jaw broken stone opportunity to become very sensitive, and the progression of granularity control will be more precise. Initiated by the beginning of the cyclic process, the adjustment will gradually increase, and finally reach an equilibrium state. The balance of the torsion bar by hydraulic control can drive the size of the opening of the jaw plate, and thus to a certain extent, to avoid possible duplicate job and provides maximum discrimination and accuracy.

3, the use of auxiliary adjustment wedges

Wedge is used to adjust the width of the discharge opening, you can use a bolt or worm gears or chains, iron lift after so inclined, wedges installed in the rack before the two side walls of the guide groove, can only move horizontally. When the wedge is lifted, due to the relationship between the front slope along the guide groove wedges move forward, thrust plate and moving jaw is subsequently moved forward, the discharge opening width decreases. Conversely, when the wedge decreased the discharge opening width increases. SEBON Heavy Industries will be the first to use wedges as an auxiliary method applied in practice, and has been unanimously endorsed by the user, since such adjustment device can achieve stepless adjustment, do not stop when adjusting.